16 typntawmcommon PCBsolderingqhov tsis xws luag

Hauv cov txheej txheem PCB los ua ke, ntau yam tsis xws luag feem ntau tshwm sim, xws li kev sib tsoo tsis raug, overheating, bridging thiab lwm yam.Hauv qab no PCBfuture yuav piav qhia qhov qubPCB sib dhostsis xws luag thaum solder PCBs thiab yuav ua li cas kom tsis txhob nws.

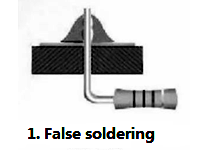

1. Tsis siv neeg soldering

Cov tsos mob tshwm sim: muaj qhov pom tseeb dub ciam teb ntawm cov khoom siv lead ua thiab cov hlau lead, los yog tooj liab ntawv ci, thiab cov khoom siv yog concave rau ciam teb.

Kev puas tsuaj: tsis ua haujlwm zoo.

Yog vim li cas: cov hlau lead ntawm cov khoom tsis raug ntxuav, tin tsis plated los yog tin yog oxidized.Cov ntawv luam tawm Circuit Board tsis tau ntxuav, thiab qhov zoo ntawm cov tshuaj tsuag flux tsis zoo.

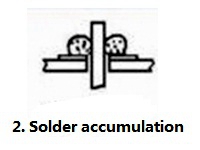

2. Solder tsub zuj zuj

Cov tsos mob tshwm sim: cov qauv sib koom ua ke yog xoob, dawb thiab lusterless.

Kev puas tsuaj: tsis muaj zog txhua yam tuaj yeem ua rau vuam tsis raug.

Yog vim li cas: tsis zoo solder zoo.Lub vuam kub tsis txaus.Thaum lub solder tsis solidified, cov khoom siv lead ua yog xoob.

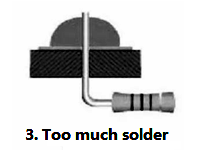

3. Ntau dhau solder

Cov yam ntxwv zoo li: lub npoo npoo yog convex.

Kev puas tsuaj: solder yog nkim thiab tsis xws luag yuav tsis yooj yim pom.

Yog vim li cas: ua haujlwm tsis raug thaum lub sij hawm soldering.

4. me ntsis solder

Cov tsos mob tshwm sim: qhov chaw vuam yog tsawg dua 80% ntawm lub ncoo, thiab lub vuam tsis tsim ib qho kev hloov pauv.

Kev puas tsuaj: tsis muaj zog txhua yam.

Yog vim li cas: solder mobility yog tsis zoo los yog ntxov ntxov solder tshem tawm.Tsis txaus flux.Lub sijhawm vuam yog luv heev.

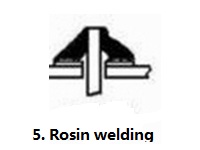

5. Rosin vuam

Cov yam ntxwv nta: muaj rosin slag nyob rau hauv weld.

Kev puas tsuaj: lub zog tsis txaus, kev ua haujlwm tsis zoo, qee zaum tawm thiab tawm.

Yog vim li cas: muaj ntau lub vuam tshuab los yog vuam tsis ua hauj lwm.Lub sijhawm vuam tsis txaus thiab cua sov.Cov yeeb yaj kiab oxide nto tsis raug tshem tawm.

6. Tshaj dhau

Cov yam ntxwv nta: dawb solder sib koom, tsis muaj xim hlau luster, ntxhib nto.

Kev puas tsuaj: lub ncoo yog yooj yim tev tawm thiab lub zog txo.

Yog vim li cas: lub zog ntawm cov hlau soldering yog loj heev, thiab lub sij hawm cua sov yog ntev heev.

7. Txias vuam

Cov tsos mob tshwm sim: Qhov saum npoo yog granular, thiab qee zaum yuav muaj kab nrib pleb.

Kev puas tsuaj: Tsawg zog thiab tsis zoo conductivity.

Yog vim li cas: lub solder yog shaken ua ntej nws solidifies.

8. Tsis zoo infiltration

Cov tsos mob tshwm sim: qhov sib cuam tshuam ntawm solder thiab vuam yog loj heev thiab tsis du.

Kev puas tsuaj: tsis muaj zog, tsis muaj kev nkag los yog lub sij hawm-rau thiab tawm.

Yog vim li cas: lub weldment tsis huv.Flux tsis txaus lossis tsis zoo.Lub weldment tsis yog tag nrho rhuab.

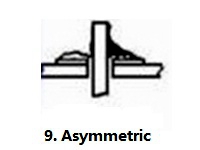

9. Asymmetrical

Cov tsos mob tshwm sim: solder tsis ntws hla lub ncoo.

Kev puas tsuaj: tsis muaj zog.

Yog vim li cas: lub solder muaj tsis zoo fluidity.Tsis txaus flux lossis tsis zoo.Cov cua sov tsis txaus.

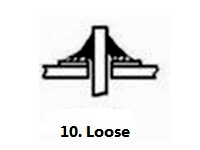

10. Lov

Cov yam ntxwv tshwm sim: Cov hlau lossis cov khoom siv lead ua tuaj yeem txav tau.

Kev puas tsuaj: tsis zoo los yog tsis ua.

Yog vim li cas: ua ntej lub solder solidifies, cov hlau lead txav mus ua voids.Cov hmoov txhuas tsis ua haujlwm zoo.

11. Cub

Cov yam ntxwv tsos: ntse.

Kev puas tsuaj: tsis zoo li qub, yooj yim rau kev hla

Yog vim li cas: flux tsawg dhau thiab lub sijhawm cua sov ntev dhau.Lub kaum sab xis ntawm cov hlau soldering yog tsis tsim nyog.

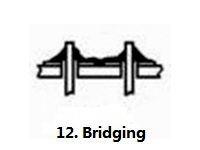

12. Kev hla kev

Cov yam ntxwv tshwm sim: cov kab uas nyob ib sab txuas nrog.

Kev puas tsuaj: hluav taws xob luv luv.

Yog vim li cas: solder ntau dhau.Lub kaum sab xis ntawm retraction ntawm soldering hlau.

13. Pinhole

Cov tsos mob tshwm sim: kev tshuaj xyuas qhov muag lossis lub tshuab hluav taws xob qis tuaj yeem pom qhov.

Kev puas tsuaj: lub zog tsis txaus, sib koom ua ke yooj yim rau corrode.

Yog vim li cas: qhov sib txawv ntawm cov hlau lead thiab lub ncoo qhov loj heev.

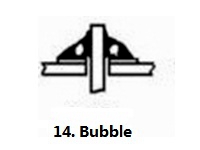

14. Npuas

Cov tsos mob tshwm sim: muaj qhov hluav taws kub ua pa tawm ntawm lub hauv paus ntawm cov hlau lead, thiab cov kab noj hniav yog muab zais rau hauv.

Kev puas tsuaj: kev ua haujlwm ib ntus, tab sis nws yooj yim ua rau tsis zoo rau lub sijhawm ntev.

Yog vim li cas: qhov sib txawv ntawm cov hlau lead thiab vuam disc qhov yog loj.Tsis zoo txhuas infiltration.Lub sijhawm vuam ntawm ob sab txuas los ntawm lub qhov yog ntev, thiab huab cua hauv qhov nthuav dav.

15. Copper foil warped

Cov tsos mob tshwm sim: cov ntawv ci tooj liab yog tev tawm ntawm cov ntawv luam tawm.

Kev puas tsuaj: PCB puas lawm.

Yog vim li cas: lub sijhawm vuam ntev dhau lawm thiab qhov kub thiab txias siab dhau.

16. Yuav muab tshem tawm

Cov yam ntxwv tshwm sim: cov pob qij txha tev tawm ntawm cov ntawv ci tooj liab (tsis yog tooj liab ntawv ci thiab PCB).

Kev puas tsuaj: qhib Circuit Court.

Yog vim li cas: tsis zoo hlau txheej ntawm ncoo.

PCBFuture muab tag nrho cov kev pabcuam PCB sib dhos, suav nrog kev tsim khoom PCB, kev tsim khoom thiab kev sib dhos PCB.PebTurnkey PCB kev pabcuamtshem tawm koj qhov kev xav tau los tswj ntau tus neeg muag khoom nyob rau ntau lub sijhawm, ua rau muaj kev ua tau zoo thiab kev siv nyiaj ntau dua.Raws li lub tuam txhab ua tau zoo, peb tau teb tag nrho cov kev xav tau ntawm cov neeg siv khoom, thiab tuaj yeem muab cov kev pabcuam raws sijhawm thiab tus kheej uas cov tuam txhab loj tsis tuaj yeem xyaum.Peb tuaj yeem pab koj kom tsis txhob muaj PCB soldering tsis xws luag hauv koj cov khoom.

Post lub sij hawm: Nov-06-2021