Vim li cas peb yuav tsum ntsaws lub vias hauv PCB?

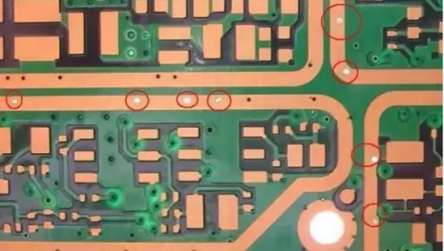

Txhawm rau ua kom tau raws li qhov xav tau ntawm cov neeg siv khoom, lub qhov ntawm lub qhov hauv Circuit Board yuav tsum tau ntsaws.Tom qab ntau qhov kev xyaum, cov txheej txheem txhuas txhuas ntsaws qhov yog hloov pauv, thiab cov net dawb yog siv los ua kom tiav qhov kev tiv thaiv vuam thiab ntsaws qhov ntawm lub rooj tsav xwm hauv Circuit Court, uas tuaj yeem ua rau cov khoom ruaj khov thiab txhim khu kev qha.

Via qhov plays lub luag haujlwm tseem ceeb hauv kev sib cuam tshuam ntawm circuits.Nrog rau txoj kev loj hlob ntawm kev lag luam hluav taws xob, nws kuj txhawb txoj kev loj hlob ntawm PCB, thiab tso siab rau cov kev xav tau ntau dua rauPCB fabrication thiab sib dhostshuab.Ntawm lub qhov ntsaws tshuab tau los ua, thiab cov kev cai hauv qab no yuav tsum tau ua tiav:

(1) Cov tooj liab hauv lub qhov ntawm lub qhov yog txaus, thiab lub npog ntsej muag tuaj yeem ntsaws lossis tsis tau;

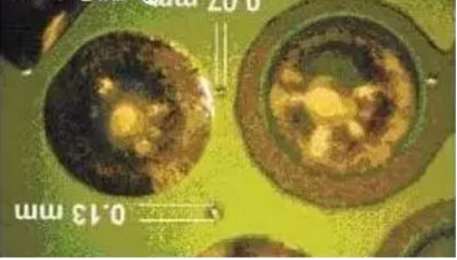

(2) Yuav tsum muaj cov tin thiab txhuas nyob rau hauv lub qhov ntawm lub qhov, nrog ib tug tej yam thickness yuav tsum tau (4 microns), tsis muaj solder tiv thaiv number case rau hauv lub qhov, ua rau tin hlaws dai nyob rau hauv lub qhov;

(3) Yuav tsum muaj qhov sib txawv ntawm cov kua nplaum hauv lub qhov ntawm lub qhov, uas tsis yog pob tshab, thiab yuav tsum tsis muaj tin nplhaib, tin hlaws thiab tiaj tus.

Nrog rau txoj kev loj hlob ntawm cov khoom siv hluav taws xob nyob rau hauv cov kev taw qhia ntawm "lub teeb, nyias, luv luv thiab me", PCB kuj txhim kho mus rau qhov siab ceev thiab siab nyuaj.Yog li ntawd, ib tug loj tus naj npawb ntawm SMT thiab BGA PCBs tau tshwm sim, thiab cov neeg muas zaub yuav tsum tau ntsaws qhov thaum mounting Cheebtsam, uas mas muaj tsib functions:

Nrog rau txoj kev loj hlob ntawm cov khoom siv hluav taws xob nyob rau hauv cov kev taw qhia ntawm "lub teeb, nyias, luv luv thiab me", PCB kuj txhim kho mus rau qhov siab ceev thiab siab nyuaj.Yog li ntawd, ib tug loj tus naj npawb ntawm SMT thiab BGA PCBs tau tshwm sim, thiab cov neeg muas zaub yuav tsum tau ntsaws qhov thaum mounting Cheebtsam, uas mas muaj tsib functions:

(1) Txhawm rau tiv thaiv luv luv los ntawm tin nkag mus rau hauv cov khoom nto thaum lub sij hawm PCB tshaj yoj soldering, tshwj xeeb tshaj yog thaum peb tso lub qhov ntawm lub BGA ncoo, peb yuav tsum xub ua lub plug qhov thiab ces kub plating los pab BGA soldering. .

(2) Tsis txhob flux residue hauv qhov ntawm qhov;

(3) Tom qab qhov chaw mounting thiab cov khoom sib dhos ntawm lub tshuab hluav taws xob, PCB yuav tsum nqus lub tshuab nqus tsev los ua qhov tsis zoo ntawm lub tshuab kuaj;

(4) Tiv thaiv kom tsis txhob ntog los ntawm qhov ntws mus rau hauv lub qhov, thiab ua rau tsis muaj tseeb soldering thiab cuam tshuam rau lub mount;

(5) tiv thaiv cov hlaws hlaws tsis tuaj yeem tawm thaum lub sijhawm nthwv dej, thiab ua rau luv luv.

Realization ntawm plug qhov technology rau ntawm lub qhov

RauSMT PCB sib dhosboard, tshwj xeeb tshaj yog cov mounting ntawm BGA thiab IC, ntawm lub qhov ntsaws yuav tsum tiaj tus, lub convex thiab concave ntxiv los yog rho tawm 1mil, thiab yuav tsum tsis muaj liab tin ntawm ntug ntawm lub qhov;txhawm rau ua kom tau raws li cov neeg siv khoom xav tau, los ntawm lub qhov ntsaws qhov txheej txheem tuaj yeem piav qhia raws li ntau yam, cov txheej txheem ntev ntws, kev tswj cov txheej txheem nyuaj, feem ntau muaj teeb meem xws li roj poob thaum huab cua kub leveling thiab ntsuab roj solder resistance test thiab roj tawg tom qab. kho.Raws li cov xwm txheej tiag tiag ntawm kev tsim khoom, peb sau cov txheej txheem txuas ntau qhov ntawm PCB, thiab ua rau qee qhov kev sib piv thiab kev piav qhia hauv cov txheej txheem thiab qhov zoo thiab qhov tsis zoo:

Nco tseg: lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm huab cua kub yog siv cov cua kub kom tshem tawm cov khoom siv ntau dhau ntawm cov ntawv luam tawm ntawm lub rooj tsavxwm thiab hauv lub qhov, thiab cov khoom seem yog sib npaug ntawm cov ntaub qhwv, tsis thaiv cov kab thiab cov ntsiab lus ntim. , uas yog ib txoj hauv kev ntawm kev kho deg ntawm cov ntawv luam tawm Circuit Board.

1. Plug qhov txheej txheem tom qab cua kub leveling: phaj nto kuj welding → HAL → plug qhov → curing.Cov txheej txheem tsis-plug yog saws rau kev tsim khoom.Tom qab cua kub leveling, aluminium screen lossis number case blocking screen yog siv los ua kom tiav los ntawm lub qhov ntsaws ntawm tag nrho cov fortresses xav tau los ntawm cov neeg muas zaub.Plug qhov number case tuaj yeem ua tus number case photosensitive lossis thermosetting number case, nyob rau hauv cov ntaub ntawv ntawm kom ntseeg tau cov xim ntawm cov yeeb yaj kiab ntub dej, qhov ntsaws qhov number case yog qhov zoo tshaj plaws los siv tib tus cwj mem raws li lub rooj tsavxwm.Cov txheej txheem no tuaj yeem ua kom ntseeg tau tias lub qhov los ntawm lub qhov yuav tsis poob roj tom qab cua kub theem, tab sis nws yog ib qho yooj yim ua rau lub qhov ntsaws qhov number case ua paug rau lub phaj nto thiab tsis sib xws.Nws yog ib qho yooj yim rau cov neeg siv khoom los ua kom tsis muaj tseeb thaum lub sij hawm mounting (tshwj xeeb tshaj yog BGA).Yog li, ntau tus neeg siv khoom tsis lees txais cov qauv no.

2. Plug qhov txheej txheem ua ntej cua kub leveling: 2.1 plug qhov nrog aluminium ntawv, solidify, grind lub phaj, thiab ces hloov cov duab.Cov txheej txheem no siv CNC drilling tshuab los laum tawm cov ntawv txhuas uas yuav tsum tau ntsaws lub qhov, ua cov phaj phaj, ntsaws lub qhov, xyuas kom lub qhov ntsaws qhov puv, ntsaws lub qhov number case, thermosetting number case kuj siv tau.Nws cov yam ntxwv yuav tsum yog siab hardness, me me shrinkage hloov ntawm resin, thiab zoo adhesion nrog lub qhov phab ntsa.Cov txheej txheem thev naus laus zis yog raws li hauv qab no: pretreatment → ntsaws qhov → sib tsoo phaj → qauv hloov → etching → phaj nto kuj vuam.Txoj kev no tuaj yeem ua kom ntseeg tau tias lub qhov los ntawm lub qhov ntsaws qhov yog du, thiab cua kub theem yuav tsis muaj teeb meem zoo xws li cov roj tawg thiab cov roj poob ntawm lub qhov ntug.Txawm li cas los xij, cov txheej txheem no yuav tsum tau ua kom tuab ntawm tooj liab ib zaug los ua kom cov tooj liab tuab ntawm lub qhov phab ntsa raws li tus neeg siv khoom tus qauv.Yog li ntawd, nws muaj cov kev xav tau siab rau tooj liab plating ntawm tag nrho cov phaj thiab kev ua haujlwm ntawm lub phaj grinder, thiaj li yuav xyuas kom meej tias cov resin ntawm tooj liab nto yog tshem tawm tag nrho, thiab tooj liab nto yog huv si thiab tsis muaj kuab paug.Ntau lub chaw tsim khoom PCB tsis muaj cov txheej txheem ua tooj liab ib zaug, thiab kev ua haujlwm ntawm cov khoom siv tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua, yog li cov txheej txheem no tsis tshua siv hauv PCB factories.

(Lub qhov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khawm)

We are helpful, attentive and supportive with a proactive approach to help you win in competitive markets. For more information, please email to service@pcbfuture.com.

Lub sij hawm xa tuaj: Plaub Hlis-01-2021